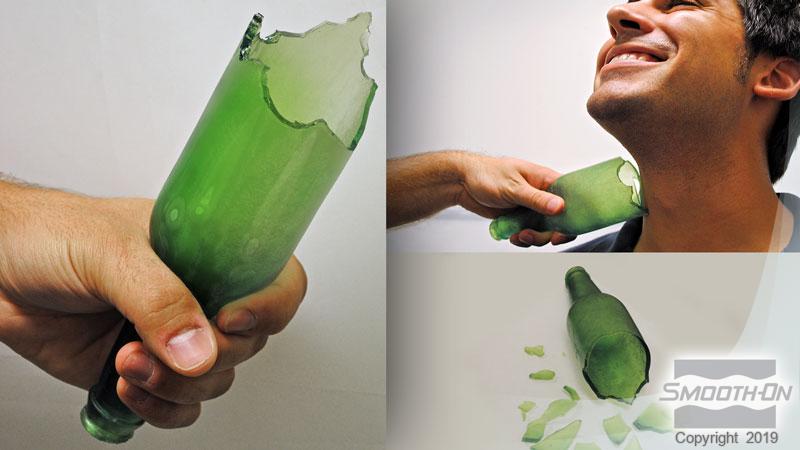

Smooth-On Rubber Glass™

By A Mystery Man Writer

Last updated 02 Jun 2024

lt;p><strong>Rubber Glass™</strong> is a platinum-catalyzed silicone rubber product developed specifically for special effects and display applications. Two liquids (1 Part A + 1 Part B) are mixed together and poured into a container.</p> <p></p> <p>The mixture cures overnight to a solid water clear rubber that can then be easily broken or “crumbled” into pieces that look exactly like broken glass, ice or diamonds. Vibrant colors are possible by adding <strong>Silc-Pig™</strong> liquid color pigments.</p> <p><strong>Rubber Glass™</strong> can be used to create a variety of special effects (i.e. simulated broken glass where human contact is required) and model effects (i.e. simulated ice or water). It can also be used for electronic encapsulation applications.</p> <p></p> <p>Instructions</p> <p><strong>MEASURING & MIXING</strong></p> <p>Materials should be stored and used in a warm environment (73°F/23°C). This product has a limited shelf life and should be use as soon as possible. Mixing containers and stirring sticks should be made of plastic and must be clean and dry. Wear safety glasses, long sleeves and vinyl gloves to minimize contamination risk.</p> <p>Dispense One Part A and One Part B by weight or volume into mixing container. Mix thoroughly for at least three minutes, making absolutely sure that you scrape the sides and bottom of your container several times.</p> <p>Do not whip or agitate material as this may cause air bubbles. If completely bubble free castings are required, vacuum degassing material prior to pouring will eliminate all bubbles.</p> <p><strong>POURING & CURING</strong></p> <p><strong>Pouring</strong> - Pour mixture into a plastic container or mold (ice cube trays or plastic cups made of polyethylene work well). If pouring into or over other surfaces, be aware that cure inhibition is possible (see section -“<strong>Cure Inhibition</strong>”). If casting into silicone molds, a release agent (<strong>Ease Release™ 200</strong> available from Smooth-On) is required.</p> <p><strong>Curing</strong> - Let cure overnight at room temperature (73°F/23°C). Do not cure rubber where temperature is less than 65°F /18°C. You can cure the material faster by applying mild heat (150°F/60°C).</p> <p><strong>INHIBITION & PERFORMANCE</strong></p> <p><strong>Cure Inhibition</strong> - If compatibility between the rubber and the surface that you are pouring rubber over is a concern, a small scale test is recommended. Materials found to cause cure inhibition include sulfur-based modeling clays and latex rubber. If pouring <strong>Rubber Glass™</strong> over a model surface that you think might cause inhibition, apply a “barrier coat” of clear acrylic lacquer sprayed directly over all surfaces that will come in contact with the <strong>Rubber Glass™</strong> is usually effective.</p> <p><strong>Adhesion:</strong> <strong>Rubber Glass™</strong> may stick to some surfaces such as glass. A coating of <strong>Ease Release™ 200</strong> will facilitate release from any surface.</p> <p><strong>Material Performance</strong> - Once material has fully cured it can be removed from the container or mold. Cured <strong>Rubber Glass™</strong> is now ready to be displayed as is or broken/crumbled for your specific application.</p> <p><strong>Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.</strong></p> <p></p> <p></p>

Rubber Glass™ is a platinum-catalyzed silicone rubber product developed specifically for special effects and display applications. Two liquids (1 Part A + 1 Part B) are mixed together and poured into a container. The mixture cures overnight to a solid water clear rubber that can then be easily broken or “crumbled” into pieces that look exactly like broken glass, ice or diamonds. Vibrant colors are possible by adding Silc-Pig™ liquid color pigments. Rubber Glass™ can be used to create a variety of special effects (i.e. simulated broken glass where human contact is required) and model effects (i.e. simulated ice or water). It can also be used for electronic encapsulation applications. Instructions MEASURING & MIXING Materials should be stored and used in a warm environment (73°F/23°C). This product has a limited shelf life and should be use as soon as possible. Mixing containers and stirring sticks should be made of plastic and must be clean and dry. Wear safety glasses, long sleeves and vinyl gloves to minimize contamination risk. Dispense One Part A and One Part B by weight or volume into mixing container. Mix thoroughly for at least three minutes, making absolutely sure that you scrape the sides and bottom of your container several times. Do not whip or agitate material as this may cause air bubbles. If completely bubble free castings are required, vacuum degassing material prior to pouring will eliminate all bubbles. POURING & CURING Pouring - Pour mixture into a plastic container or mold (ice cube trays or plastic cups made of polyethylene work well). If pouring into or over other surfaces, be aware that cure inhibition is possible (see section -“Cure Inhibition”). If casting into silicone molds, a release agent (Ease Release™ 200 available from Smooth-On) is required. Curing - Let cure overnight at room temperature (73°F/23°C). Do not cure rubber where temperature is less than 65°F /18°C. You can cure the material faster by applying mild heat (150°F/60°C). INHIBITION & PERFORMANCE Cure Inhibition - If compatibility between the rubber and the surface that you are pouring rubber over is a concern, a small scale test is recommended. Materials found to cause cure inhibition include sulfur-based modeling clays and latex rubber. If pouring Rubber Glass™ over a model surface that you think might cause inhibition, apply a “barrier coat” of clear acrylic lacquer sprayed directly over all surfaces that will come in contact with the Rubber Glass™ is usually effective. Adhesion: Rubber Glass™ may stick to some surfaces such as glass. A coating of Ease Release™ 200 will facilitate release from any surface. Material Performance - Once material has fully cured it can be removed from the container or mold. Cured Rubber Glass™ is now ready to be displayed as is or broken/crumbled for your specific application. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Rubber Glass™ is a platinum-catalyzed silicone rubber product developed specifically for special effects and display applications. Two liquids (1 Part A + 1 Part B) are mixed together and poured into a container. The mixture cures overnight to a solid water clear rubber that can then be easily broken or “crumbled” into pieces that look exactly like broken glass, ice or diamonds. Vibrant colors are possible by adding Silc-Pig™ liquid color pigments. Rubber Glass™ can be used to create a variety of special effects (i.e. simulated broken glass where human contact is required) and model effects (i.e. simulated ice or water). It can also be used for electronic encapsulation applications. Instructions MEASURING & MIXING Materials should be stored and used in a warm environment (73°F/23°C). This product has a limited shelf life and should be use as soon as possible. Mixing containers and stirring sticks should be made of plastic and must be clean and dry. Wear safety glasses, long sleeves and vinyl gloves to minimize contamination risk. Dispense One Part A and One Part B by weight or volume into mixing container. Mix thoroughly for at least three minutes, making absolutely sure that you scrape the sides and bottom of your container several times. Do not whip or agitate material as this may cause air bubbles. If completely bubble free castings are required, vacuum degassing material prior to pouring will eliminate all bubbles. POURING & CURING Pouring - Pour mixture into a plastic container or mold (ice cube trays or plastic cups made of polyethylene work well). If pouring into or over other surfaces, be aware that cure inhibition is possible (see section -“Cure Inhibition”). If casting into silicone molds, a release agent (Ease Release™ 200 available from Smooth-On) is required. Curing - Let cure overnight at room temperature (73°F/23°C). Do not cure rubber where temperature is less than 65°F /18°C. You can cure the material faster by applying mild heat (150°F/60°C). INHIBITION & PERFORMANCE Cure Inhibition - If compatibility between the rubber and the surface that you are pouring rubber over is a concern, a small scale test is recommended. Materials found to cause cure inhibition include sulfur-based modeling clays and latex rubber. If pouring Rubber Glass™ over a model surface that you think might cause inhibition, apply a “barrier coat” of clear acrylic lacquer sprayed directly over all surfaces that will come in contact with the Rubber Glass™ is usually effective. Adhesion: Rubber Glass™ may stick to some surfaces such as glass. A coating of Ease Release™ 200 will facilitate release from any surface. Material Performance - Once material has fully cured it can be removed from the container or mold. Cured Rubber Glass™ is now ready to be displayed as is or broken/crumbled for your specific application. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

SLIDE™ STD Product Information

Silipint's biggest silicone cup to date, the 22oz Bomber. Supersized and perfect for hot and cold summertime drinks.

Silicone Bomber Glass - 22 oz Lilly Pilly

Smooth-On, Inc., Mold Making & Casting Materials

QUICKWEED Sub Block 20

Smooth-On Rubber Glass™

Smooth-On, Inc., Mold Making & Casting Materials

Rubber Glass™ Product Information

Rubber Glass™, Water-Clear Silicone Rubber

Smooth-On, Inc., Mold Making & Casting Materials

Boo Glass, 12 Rubber Grommet Beaker Base Bong

Rubber Glass™, Water-Clear Silicone Rubber

SORTA-Clear Series rubbers are premium water white translucent silicone rubbers (platinum catalyst) which cure at room temperature with negligible shrinkage. Sorta Clear 37 has Shore 37A hardness and features high tensile and tear strength. This product also offers the convenience of a 1A:1B by volume mix ratio. SORTA-Clear silicones are ideal for making prototype, jewelry or other molds of any configuration where model visibility is important (i.e.

Smooth-On SORTA-Clear 37 Clear Silicone Rubber - Trial Unit

Rebound™ Series, Brushable Platinum Silicone Rubber

Recommended for you

-

Smooth-On Mold Max 30, Gallon Set02 Jun 2024

Smooth-On Mold Max 30, Gallon Set02 Jun 2024 -

Smooth-On Oomoo 30 Silicone Rubber02 Jun 2024

Smooth-On Oomoo 30 Silicone Rubber02 Jun 2024 -

Smooth-On Equinox Slow Silicone Putty Kit - 16 oz.02 Jun 2024

Smooth-On Equinox Slow Silicone Putty Kit - 16 oz.02 Jun 2024 -

Smooth-On: Silicone Rubber02 Jun 2024

Smooth-On: Silicone Rubber02 Jun 2024 -

Pourable Silicone Starter Kit Product Information02 Jun 2024

Pourable Silicone Starter Kit Product Information02 Jun 2024 -

China Silicone Strap With Smooth Feeling Coating Manufacturer and02 Jun 2024

China Silicone Strap With Smooth Feeling Coating Manufacturer and02 Jun 2024 -

FormX Webshop02 Jun 2024

FormX Webshop02 Jun 2024 -

Smooth-On Mold Star 31T Silicone Mold Making Rubber - Trial Unit02 Jun 2024

Smooth-On Mold Star 31T Silicone Mold Making Rubber - Trial Unit02 Jun 2024 -

Smooth-On Rebound 25 Silicone Rubber02 Jun 2024

Smooth-On Rebound 25 Silicone Rubber02 Jun 2024 -

Body Double™ Standard Set Life Casting Silicone, Trial Unit – Highwater Clays02 Jun 2024

Body Double™ Standard Set Life Casting Silicone, Trial Unit – Highwater Clays02 Jun 2024

You may also like

-

Dark Aesthetic Room Moody Art Night Sky Print Fairycore Decor Goth Decor Witch Decor Witchy Academia Witchy Decor Bedroom02 Jun 2024

Dark Aesthetic Room Moody Art Night Sky Print Fairycore Decor Goth Decor Witch Decor Witchy Academia Witchy Decor Bedroom02 Jun 2024 -

River Rock #4, Shipped or Delivered02 Jun 2024

River Rock #4, Shipped or Delivered02 Jun 2024 -

80# Buffered Text - Archivart® Standard Paper02 Jun 2024

80# Buffered Text - Archivart® Standard Paper02 Jun 2024 -

Basket Grass Craft Shred Confetti Raffia Paper Filler For - Temu02 Jun 2024

Basket Grass Craft Shred Confetti Raffia Paper Filler For - Temu02 Jun 2024 -

STO Sterling Silver Oxidized 2-Rib Spacer Bead02 Jun 2024

STO Sterling Silver Oxidized 2-Rib Spacer Bead02 Jun 2024 -

Las Plastilinas más utilizadas ⋆ Plastilina, jugando con creatividad02 Jun 2024

Las Plastilinas más utilizadas ⋆ Plastilina, jugando con creatividad02 Jun 2024 -

Rosco Lens Tissue 100 Sheets 4 X 602 Jun 2024

Rosco Lens Tissue 100 Sheets 4 X 602 Jun 2024 -

ANSOMO Black and White Party Decorations and Supplies, for Baby Shower and Birthday Graduation Bachelorette with Paper Fan and Tassel Garland02 Jun 2024

ANSOMO Black and White Party Decorations and Supplies, for Baby Shower and Birthday Graduation Bachelorette with Paper Fan and Tassel Garland02 Jun 2024 -

Aotiwe Tapestry Wall Hanging Kit, Hanging Wall Art Zebra Polyester Black White 300x260CM Indoor for Home : Home & Kitchen02 Jun 2024

Aotiwe Tapestry Wall Hanging Kit, Hanging Wall Art Zebra Polyester Black White 300x260CM Indoor for Home : Home & Kitchen02 Jun 2024 -

These are the Best First Wedding Anniversary Gifts for 202302 Jun 2024

These are the Best First Wedding Anniversary Gifts for 202302 Jun 2024